About Sake

bottled a tradition and innovation

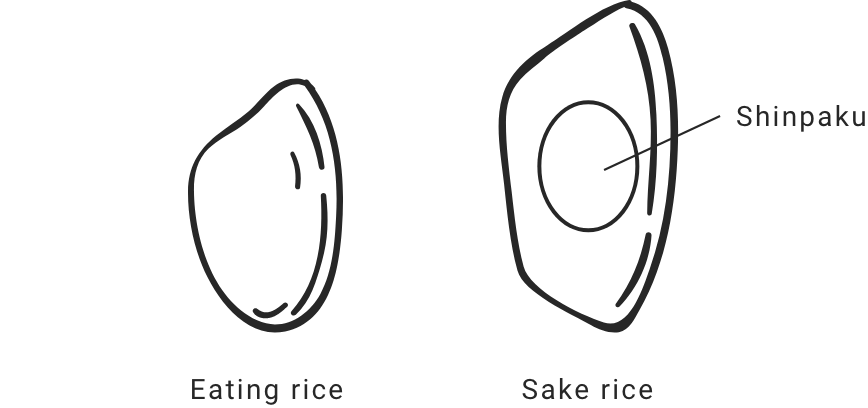

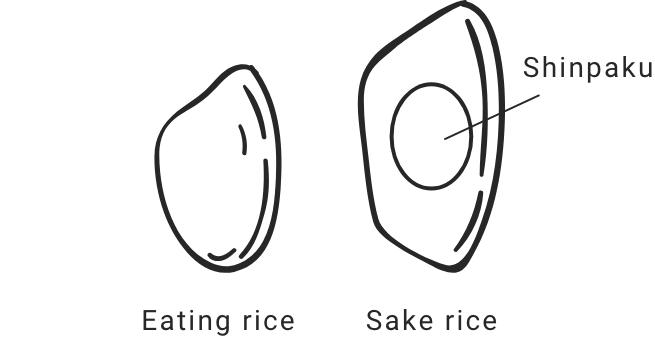

Sake Rice

rice used for sake is called “sakamai”. sake rice is different from rice used for eating. the rice used for sake has a larger proportion 0f starch in the center of the grain. the reason for this is that sake rice has as much of the rice removed as possible except for the starchy core to give the sake a clear taste. the core is composed of starch and protein. rice koji is made from this starchy milled rice core plus koji mold. koji is a kind of cultivated mold used to change rice starch into sugar. this is why sake breweries use rice with a high starch and protein content. also, if the rice is damaged during the milling process, the protein will be damaged, making it difficult to make good sake. therefore, the rice is milled using a special brewer’s milling machine, so that the rice slowly becomes round.

Koji Room

The Koji room is a special room for making rice koji - a mixture of steamed rice and brewer’s mold called TANE KOUJI (MOYASHI) This room is traditionally made of cedar. The reason for this is that when the koji changes the rice starch to sugar the mold emits heat. This causes the temperature in this room to rise. The room is built like a sauna because the temperature must be kept at 104F. The temperature is controlled by a small air vent in the corner of the room. The koji rice mixture is spread into wooden boxes. It takes forty-three hours at 104F for the koji rice mixture to be ready for fermentation.

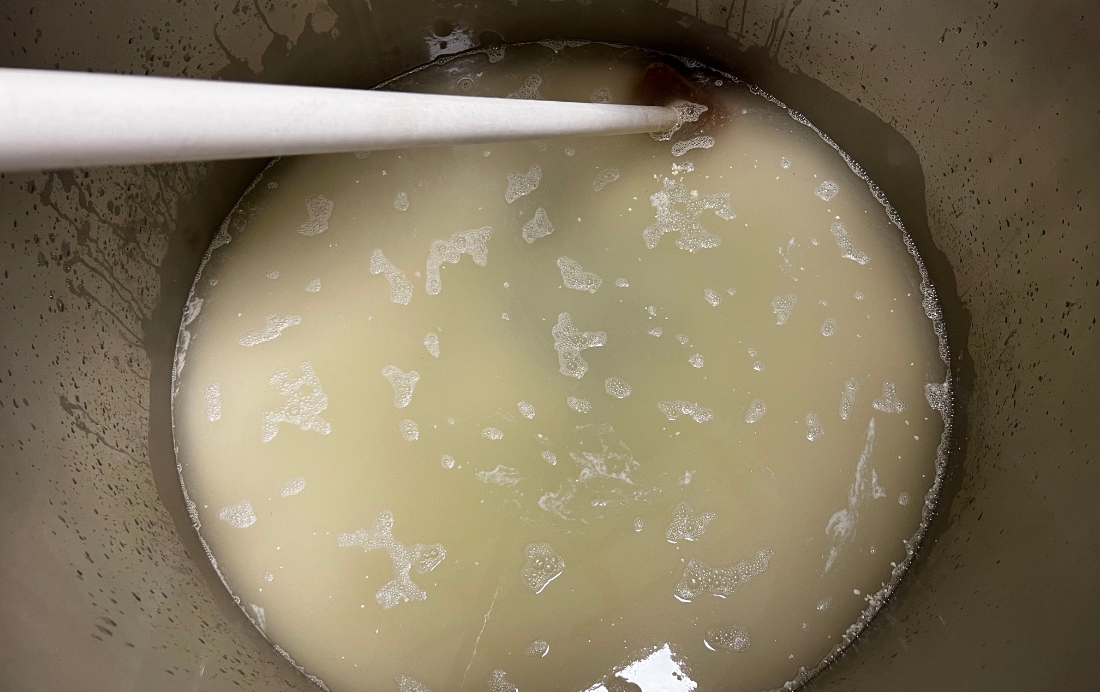

Fermentation

fermentation of the sake begins in a small tank.initially,mater,yeast,the koji rice mixture and some plain steamed rice are added to start fermentation.two days later,the samu items are added again.this is repeated three times.this is known as the three-stage sake brewing process.sake brewing takes place during the cold season which helps control the speed of the fermentation process.fermentation of the sake takes about 20 to 30 days.after that,the sake is moved to the pressing process.

Pressong

to extract the sake, the fermented rice mixture is placed in special cotton bags called a sake bag. this bag is made of a material that can withstand the pressure of squeezing the sake. the sake that has finished fermenting is placed in these bags and then placed inside a box called a fune. fune is the japanese word for boat. it is probably called a boat because of its similarity in appearance. the sake bags are stacked in this box and pressed for 50 hours. during the process, the sake bags are reloaded several times.

the strained residue in the bags after the sake is pressed out is called sake kasu and can be used to marinate fish or vegetables.

Nigori Sake

once the sake is finished being pressed, it is transferred to a tank. the sake is then left to rest for approximately ten days. this is to separate the cloudy sake from the clear sake. nigori-sake is formed when yeast that has finished fermentation settles. after ten days, the cloudy nigori sake is removed from the tank. this nigori sake should be drunk within ten days. because it is still fermenting, gas is produced in the bottle and if stored at room temperature or shaken, it can explode. it must be handled with care. only sake breweries have this fresh, mild, slightly carbonated sake.

Pasteurization(hiire)

finally, clear sake is divided into fresh (draft) sake and pasteurized sake. nama-shu, the fresh unpasteurized sake, is filtered before being bottled and shipped. it must be stored in a refrigerator to enjoy its fresh taste. the remaining sake, undergoes a process called hi-ire. this is a sterilization technique that has been practiced for about 250 years. after the sake is bottled, it is placed in a vat of warm water. the temperature of the sake is then raised to 140f. this sterilizes any trace amounts of yeast remaining in the sake. the sake is then stored in a cool sake cellar during the summer and shipped as “new batch” sake (hiyaoroshi) in the fall. sake that has rested through the summer becomes more mellow.